What is a zero liquid discharge treatment system?

Handle variations in waste contamination and flow

Allow for required chemical volumes adjustments

Recover around 95% of your liquid waste for reuse

Treat and retrieve valuable by-products from your waste (i.e. salts and brines)

Produce a dry, solid cake for disposal

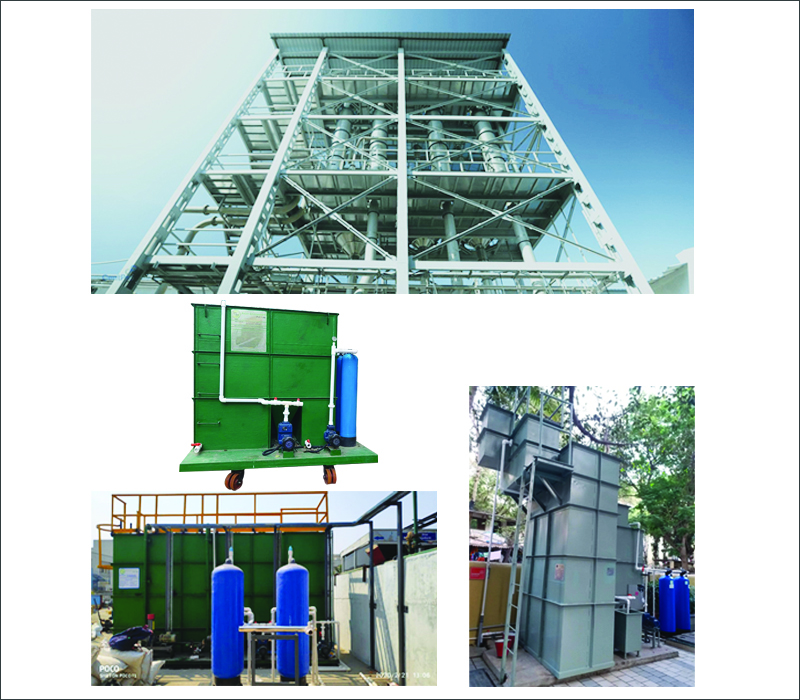

What’s included in a basic ZLD treatment system?

The exact components of a ZLD treatment system will largely depend on (1.) the volume of dissolved material present in the waste, (2.) the system’s required flow rate, and (3.) what specific contaminants are present. But in general, a basic ZLD treatment system typically includes some type of:

Clarifier and/or reactor to precipitate out metals, hardness, and silica

Chemical feed to help facilitate the precipitation, flocculation, or coagulation of any metals and suspended solids

Filter press to concentrate secondary solid waste after pre-treatment or alongside an evaporator

Ultrafiltration (UF) to remove all the leftover trace amounts of suspended solids and prevent fouling, scaling, and/or corrosion down the line of treatment

Reverse osmosis (RO) to remove the bulk of dissolved solids from the water stream in the primary phases of concentration

Brine concentrators to further concentrate the reject RO stream or reject from electrodialysis to further reduce waste volume

Evaporator for vaporizing access water in the final phases of waste concentration before crystallizer.

Crystallizer to boil off any remaining liquid, leaving you with a dry, solid cake for disposal

Depending on the needs of your plant and process, these standard components are usually adequate, however, if your plant requires a system that provides a bit more customization, there might be some features or technologies you will need to add on. Because of the broad range of industries that use ZLD and the various waste streams produced, ZLD is a highly custom process and these add ons will depend on your facility’s individual needs.