Membrane bioreactor’ (MBR) is generally a term used to define wastewater treatment processes where a perm-selective membrane, eg microfiltration or ultrafiltration, is integrated with a biological process − specifically a suspended growth bioreactor. MBRs differ from ‘polishing’ processes where the membrane is employed as a discrete tertiary treatment step with no return of the active biomass to the biological process. Almost all commercial MBR processes available today use the membrane as a filter, rejecting the solid materials which are developed by the biological process, resulting in a clarified and disinfected product effluent.

A membrane bioreactor is essentially a version of the conventional activated sludge (CAS) system While the CAS process uses a secondary clarifier or settlement tank for solid/liquid separation, an MBR uses a membrane for this function. This provides a number of advantages relating to process control and product water quality.

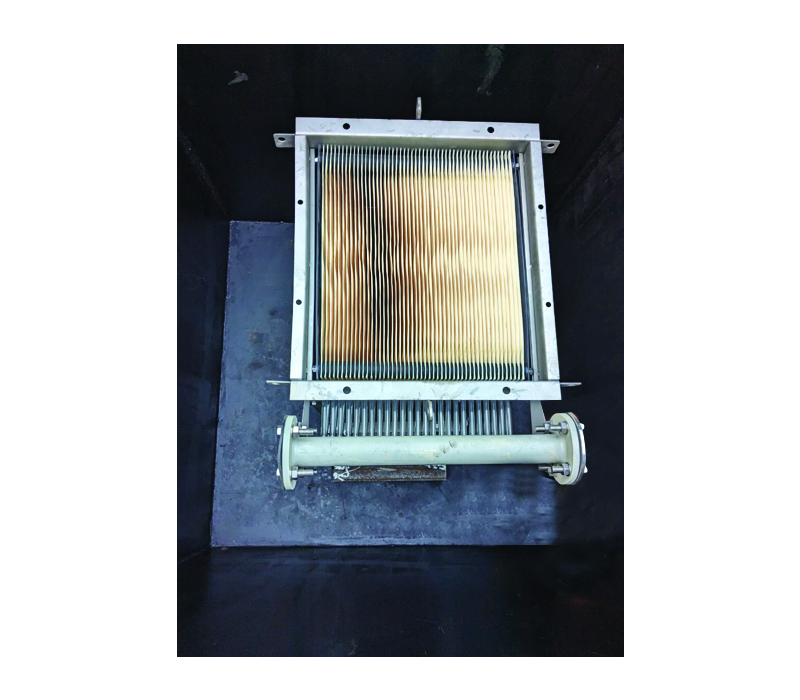

PVDF flat sheet membranes for MBR applications combine the best features of flat plate and hollow fibre technologies, such as durability, ease of use, less stringent screening requirement, small footprint, and low energy consumption. The membrane's pores are small and uniform, resulting in increased smoothness of the membrane surface leading to excellent low fouling capabilities. Compared to conventional flat plate series, flat sheet technology has increased the normalized membrane area by 50%, reduced module weight by 70%, and reduced energy consumption by 30%.

hollow fibre type with externally stiffened skin. The biological liquor is filtered by passing water through the membrane from the outside to the inside of the fibre, using the pressure differential created by a suction pump The fibre has a 1.9 mm external diameter and a 0.8 mm internal diameter. The pore has a nominal 0.04 µm diameter, providing an excellent removal capacity threshold.